By Bram Evers

Poultry Specialist

Grand Valley Fortifiers

Ammonia: Use Your Eyes and Nose

Before you can smell ammonia, you can feel it in your eyes. If your eyes start burning or watering, this is the first sign of poor air quality. It is often a particularly good indicator, but it is important to note that this only works the first few seconds, as our eyes rapidly get used to it. Often, we think the climate is better in the middle of the barn, but usually it’s remarkably similar throughout and we just do not feel or smell the ammonia anymore. If you are looking for more advanced or constant monitoring, you can use instruments like a portable emission meter, or a probe connected to your barn computer.

Dust: Use your Phone Camera

Dust is bad for humans and animals alike, but a chicken cannot even cough (more on this later)! When stepping inside a barn you may think that the air quality is fine, and you do not see a lot of dust in the air. An easy test is involves your mobile phone camera and taking a picture using the flash. It will become clear how much dust there really is. Doing this only one time is not too helpful, but if you do it every week, you will be able to compare pictures and hopefully make adjustments that improve the air quality for your birds!

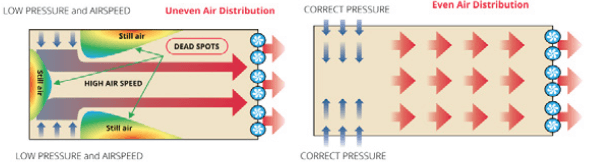

Negative Pressure and the Requirements

Using a negative pressure ventilation system is the most efficient way to accomplish air distribution for minimum ventilation. The pressure “drop” across the inlets and the amount the inlet is opened should be adjusted to ensure that the incoming air jet “sticks” to the ceiling and drops no sooner than when the fresh air has had enough time to acclimatize. The pressure drop selected will depend on the barn width, how far the incoming air jet must travel once it enters the barn, and the outside temperature (Figure 1). When outside temperatures are below 5 ⁰C (40 ⁰F), the inlet pressure drops, and opening size must be increased. A way to achieve this is to close 50% of the inlets, for example. As a result, the other open inlets, will open twice a much. The ability of the incoming air jet to stay close to the ceiling depends on the temperature differentials between outside and inside the barn. When the inlets are exclusively positioned on the side walls, always use a smoke test to ensure that the incoming air reaches the center of the barn. Smoke tests should only be done when the outside temperatures are significantly colder than inside, and when there is no wind.

Figure 1: A visual of uneven and even air distribution within a barn. (Broiler Cobb Genetics Guide, 2021)

Beware of Ammonia in Cold Weather

When it is cold, many poultry farmers choose to reduce the ventilation level in the barn to keep the barn warm and reduce heating costs. If the ventilation is set too low, this can lead to high ammonia concentrations, higher relative humidity (RH), and an increase of dust in the barn.

Poultry are Extra Sensitive to Ammonia

Extensive (international) poultry research has been done on the effects of different ammonia levels. Chickens are more sensitive to ammonia than mammals, because they do not have the ability to cough. High concentrations of ammonia lead to excessive mucus formation and cilia damage in the trachea (windpipe), eye inflammation, and E. coli infections. It has also been shown that an ammonia concentration of 50 ppm increases susceptibility to viral infections and can negatively affect resistance to viruses.

Lower Peak Production and Higher Mortality

Research shows that hens that were exposed to 200 ppm ammonia during the last 17 days in the pullet barn came into production later, had a lower production peak, and a higher mortality rate than the control group1. With breeders and layers, not only is production negatively affected, but also the egg quality. Ammonia levels above 50 ppm leads to problems with feed intake, production, and egg mass decreases after a few weeks.

What About Heat Exchangers?

With heat exchangers, the incoming outside air is heated by the outflowing barn

air to an efficiency of up to 80%. The fresh air has a lower RH, which means that

this air has a higher moisture absorption capacity (Table 1).

Table1: Benefits and drawbacks of heat exchangers.

Are you looking for more information regarding your poultry, or more specifically, ventilation?

Bram Evers, Poultry Specialist

905-329-6103 | bramevers@grandvalley.com

Jan Huisman, Production Improvement Specialist

226-753-7650 | janhuisman@grandvalley.com

Reference: Beware of Ammonia in Cold Weather (gddiergezondheid.nl)

This article was written for the Spring 2024 Central & Atlantic Poultry Grist. To read the whole Poultry Grist, click the button below.